SYDNEY, Australia—20 May 2025—GJS today debuted the ROQ IMPRESS automatic DTF heat transfer press live at PacPrint 2025, joined by its automation companions the ROQ FEED and ROQ PEEL, offering visitors the first chance in Australia to witness a complete high-speed, high-volume DTF production system in action.

With the ability to press up to 500 garments per hour, the ROQ IMPRESS demonstrates how digital decorators can now scale up production while dramatically reducing manual labour, one of the largest cost burdens for garment decorators in Australia.

“This is the first time anyone in Australia is able to see this level of DTF automation in person,” said Greg Stone, managing director, GJS. “With the ROQ IMPRESS, ROQ FEED and ROQ PEEL working together, we’re showing what’s possible when speed, consistency and scalability all come together.”

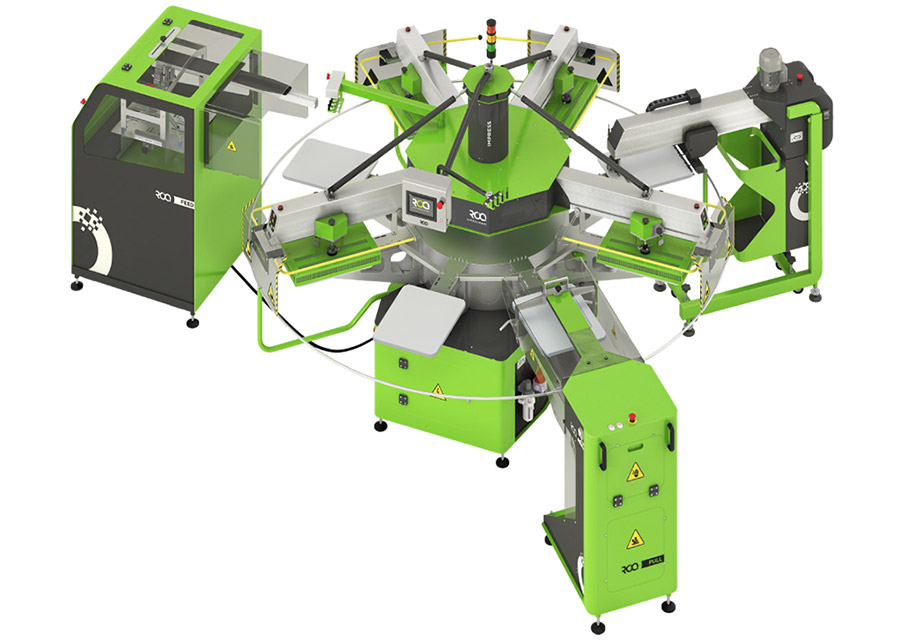

The high-production ROQ DTF automation solution on display on GJS’ stand (H68) at PacPrint includes:

The ROQ IMPRESS: A high-speed, multi-station automatic DTF heat transfer press that delivers consistent heat, time and pressure across garments of various shapes and sizes;

The ROQ FEED: An automated transfer placement device that uses laser-guided alignment and programmable recipes for flawless positioning — even on chest, sleeve or pocket prints; and

The ROQ PEEL: A hands-free peeling unit that automatically removes the transfer film, drops it into a disposal bin, and helps maintain continuous workflow without manual interruption.

Visitors will be treated to two five-minute live demonstrations daily (11:30am and 2:30pm), where GJS team members will run the equipment live on the show floor, producing finished garments and showcasing real-time production performance.

Attendees are encouraged to collect sample garments produced during the demonstrations and engage with the GJS team to explore how this automation solution can be integrated into their operations.

The ROQ DTF solutions will be complemented on the GJS stand by the Coltex D604+ DTF Printer and Powder Shaker Solution and the Secabo MultiCut Pro Automatic DTF Transfer Cutter.

The Coltex D604+ DTF Printer and Powder Shaker Solution is a 60cm wide, high-production DTF solution capable of speeds up to 27.5 linear meters per hour in dual CMYK+W configuration. It features an automatic powder shaking system, integrated dryer/curer, and an internal smoke purification system, enabling continuous operation for up to 10-hours without powder replenishment

The Secabo MultiCut Pro is an advanced flatbed cutter with an integrated conveyor belt, capable of processing typical transfer areas of 600mm x 880mm in just 30–60 seconds. It features a high-performance CCD camera for automatic registration mark detection and supports various media types, including DTF textile transfers and UV DTF adhesive films.

“The real value in everything we’re showcasing at PacPrint this year scalability,” Stone added. “These solutions allow businesses to grow without necessarily needing to grow headcount. They deliver speed and quality while lowering the dependency on manual labour. And GJS is proud to be the only supplier in Australia offering complete, end-to-end DTF solutions and sophisticated automation solutions all with the after-sales support we’re renown for,” Stone concluded.

The full range of ROQ products including all additional automation components, the Coltex D604+ and Secabo MultiCut Pro are all available Australia-wide exclusively via GJS and on display at stand H68 at PacPrint 2025.

For more information, free call 1800 457 888 or email: sales@gjs.co